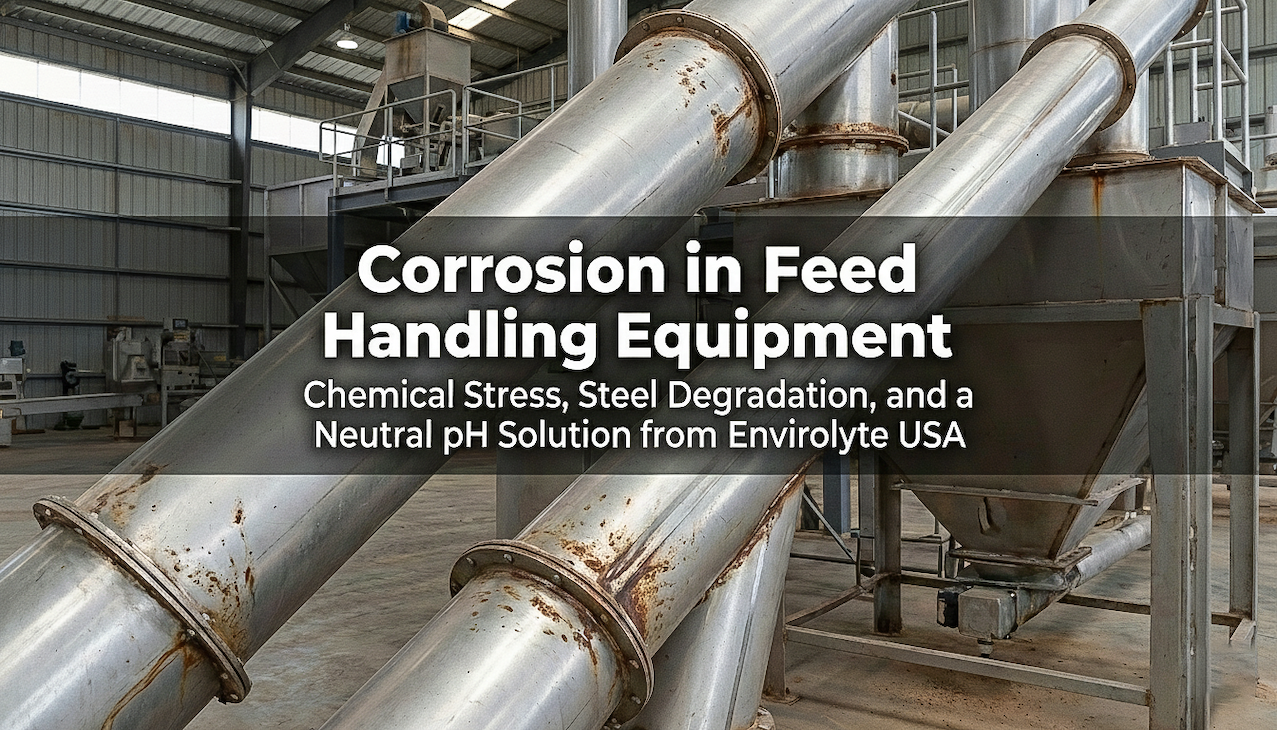

Corrosion in Feed Handling Equipment

Chemical Stress, Steel Degradation, and a Neutral pH Solution from Envirolyte USA

Stainless steel supports hygienic operations in feed and ingredient processing, but aggressive sanitation chemistry can accelerate localized corrosion and equipment degradation.In animal food ingredient and feed processing environments, stainless steel is the material of choice for conveyors, mixers, augers, tanks, piping, and CIP systems. Its corrosion resistance makes it well suited for sanitary operations. That resistance is not absolute. Frequent exposure to harsh cleaning chemistries such as strong caustics, high concentration acids, and chlorine based oxidizers can lead to localized corrosion, pitting, crevice attack, seal failure, and premature equipment degradation.

This article examines the mechanisms by which corrosion occurs in feed handling systems, explains why standard cleaning regimes contribute to material stress, and describes how Envirolyte USA neutral to mild pH, electro activated solutions support effective sanitation while reducing reliance on aggressive chemical conditions commonly associated with corrosion risk.

Why Corrosion Happens in Feed Equipment

Stainless steel corrosion resistance is primarily due to a thin passive oxide layer formed by chromium and related alloying elements on the steel surface. This passive film protects the metal by significantly slowing oxidation and metal loss under most operating conditions.

However, certain environments can disrupt this passive film and initiate localized attack.

Chloride ions, present in bleach, high salinity water, and many feed formulations, are particularly aggressive toward stainless steel passive films. Their presence is a well documented cause of pitting and crevice corrosion, which are deep, localized forms of damage that are often difficult to detect until advanced stages.

Repeated cycling between highly alkaline cleaning agents and acidic rinses introduces thermal and electrochemical stress on protective oxide films. Over time, this stress weakens corrosion resistance and increases susceptibility to localized attack.

In feed and processing environments, these factors often accumulate due to the following conditions.

- High temperature CIP cycles

- Frequent acid and alkaline cycling

- Chlorine presence from oxidizing sanitizers

- Organic build up that traps chemicals near metal surfaces

Together, these conditions contribute to equipment degradation far earlier than expected under ideal operating environments.

The Role of CIP Chemistry in Stainless Steel Stress

Clean in Place systems are widely used in food and feed processing to automate cleaning without equipment disassembly. Detergents and sanitizers are circulated through piping, tanks, and internal surfaces to remove soils and reduce microbial load.

However, commonly used CIP chemistries introduce specific corrosion stress mechanisms.

High strength caustics: High strength caustics such as sodium hydroxide at elevated temperature are effective at soil removal. When severely concentrated or left in contact for extended periods, they can attack the passive film on stainless steel surfaces.

Acid rinses: Acid rinses are used to restore pH and remove mineral scale. When applied aggressively or in frequent cycles, they further stress stainless steel passive layers, particularly under elevated temperature conditions.

Chlorine based oxidizers: Chlorine based oxidizers present a distinct corrosion risk. At elevated temperatures or concentrations above recommended limits, chloride ions can initiate pitting corrosion. Once a pit initiates, an oxygen depleted microenvironment forms that accelerates localized corrosion. Even at relatively low concentrations, repeated chloride exposure can break down the passive oxide layer and initiate pits that may propagate through wall thickness over time.

A comprehensive corrosion review in food processing documents these mechanisms and highlights their impact on long term equipment integrity.

Performance Loss and Maintenance Costs

The practical consequences of chemistry driven corrosion include the following outcomes.

Pitting of Stainless Steel

Localized cavities form beneath the protective oxide layer where chlorides accumulate. Over time, this can lead to structural weakening or through wall perforation.

Seal and Gasket Failure

Corrosive attack at interfaces compromises elastomers and gasket materials. This increases the risk of leaks, contamination events, and unplanned downtime.

Frequent Equipment Replacement

Accelerated corrosion shortens expected asset life and increases capital replacement cycles, affecting both maintenance budgets and production reliability.

Even though stainless steels such as 304 and 316 are specified for their corrosion resistance, their passive films can still fail under aggressive chemical cycling typical of conventional CIP sanitation protocols, particularly when cleaning chemistries are mismanaged or over dosed.

How Envirolyte USA Mitigates Corrosion Stress

Envirolyte USA systems generate on site electro activated solutions that support sanitation with reduced chemical aggressiveness compared to many conventional CIP chemistries.

Neutral to Mild pH Chemistry

Envirolyte solutions operate at a neutral to mild pH, reducing electrochemical stress on stainless steel passive films and supporting surface integrity over repeated sanitation cycles.

Lower Oxidizer Concentrations

Envirolyte hypochlorous acid and related electro activated solutions achieve antimicrobial activity at lower oxidant levels than many stored chlorine products. This limits chloride exposure and reduces aggressive chemical interaction with metal surfaces.

Reduced Chemical Cycling

Simplifying sanitation protocols away from repeated strong acid and alkaline sequences reduces thermal and pH stress, lowering the likelihood of passive film breakdown.

In practice, this approach supports improved material compatibility and more stable sanitation conditions while helping reduce corrosion related maintenance risk without compromising microbial control objectives.

Engineering Sanitation with Materials Longevity in Mind

Corrosion of stainless steel in feed handling and ingredient processing is not an inevitable side effect of sanitation. It is a predictable outcome of aggressive chemistries interacting with real world equipment geometry and operating environments.

Scientific literature on corrosion mechanisms, particularly chloride induced pitting and passive film degradation, supports this conclusion and helps operators understand the limits of conventional sanitation approaches.

Envirolyte USA neutral to mild pH, electro activated sanitation solutions provide an alternative approach that supports effective hygiene while reducing material stress. This enables facilities to better align food safety objectives with long term asset integrity.

References and Further Reading

- Study of the Corrosion Behavior of Stainless Steel in Food Processing Equipment

Rossi et al. Evaluation of how surface treatments, roughness, and environmental factors influence corrosion behavior and pitting susceptibility of AISI 304L stainless steel commonly used in food and feed equipment.

https://pmc.ncbi.nlm.nih.gov/articles/PMC11012613/

- Corrosion in the Food Industry and Its Control

Industry level review of corrosion mechanisms, observed failures, and control considerations for stainless steels and other metals used in food and related processing environments.

https://www.researchgate.net/publication/258222714_Corrosion_in_the_Food_Industry_and_Its_Control

- Pitting and Crevice Corrosion Mechanisms

Educational resource explaining how chloride ions and localized environments lead to passive film breakdown and pitting corrosion in stainless steels.

https://www.ssina.com/education/corrosion/pitting-and-crevice-corrosion/

- Corrosion Behavior of AISI 304 Stainless Steel

Technical review of AISI 304 stainless steel composition, passive film stability, and corrosion behavior under chloride rich and industrial processing conditions.

https://doi.org/10.1016/j.matpr.2021.11.003

Learn More About Materials Compatible Sanitation in Feed Operations

If you are evaluating sanitation strategies that reduce corrosion risk while maintaining hygiene objectives, our team can help you assess how electro activated solutions fit within your operating conditions and equipment constraints.