How we make Hypochlorous Acid:

Electrochemical Activation (ECA)

What is electrochemical water activation?

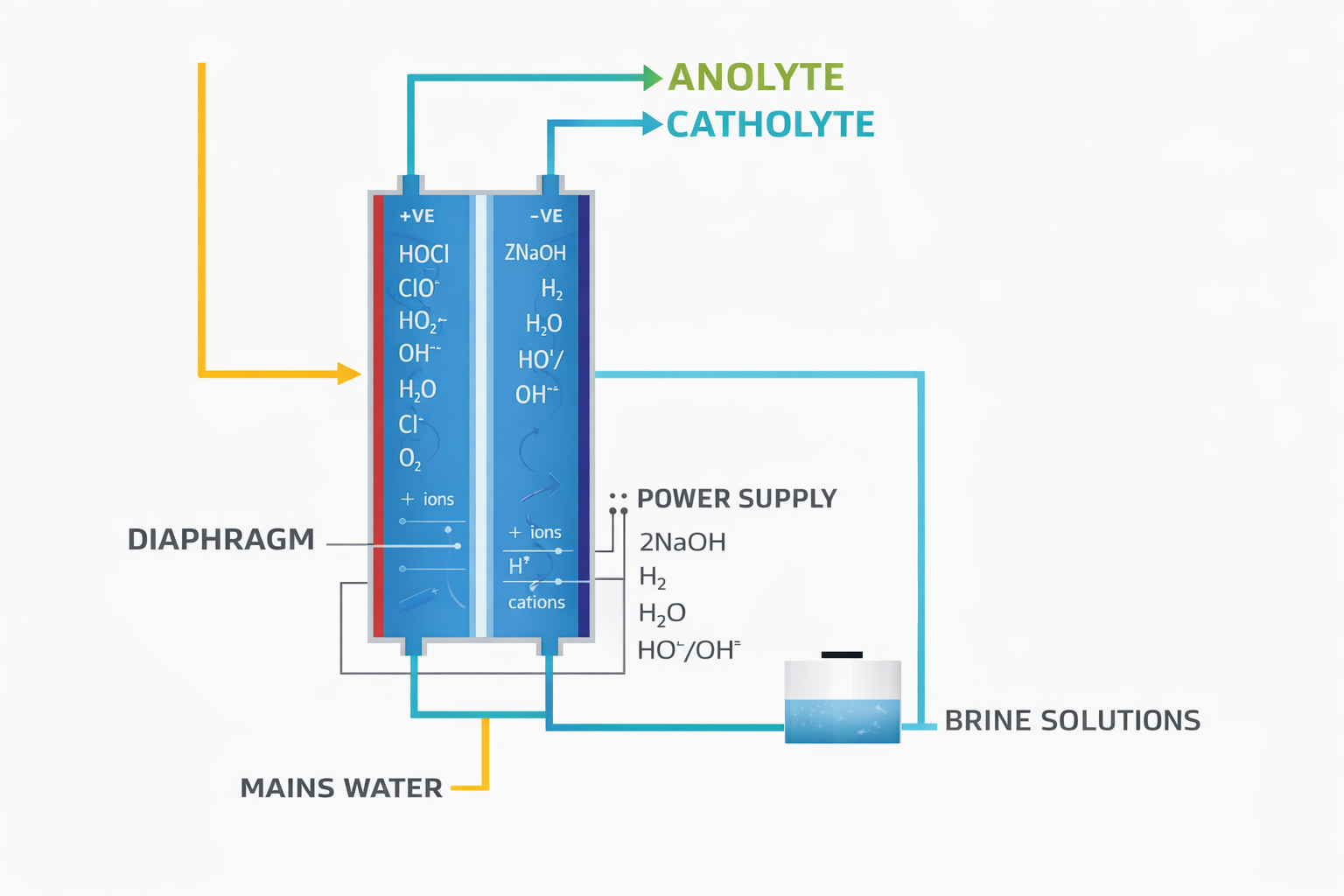

The term Electrochemical Activation comes from the English Electro Chemical Activation (ECA) . In classical chemistry, electrochemistry deals with the interrelationships between electric currents, voltages and chemical reactions, including the conversion of chemical energy into electrical energy and vice versa. One of the main focuses of this area is electrolysis, a process in which electric current is used to induce a non-spontaneous reaction, usually carried out in aqueous solutions or molten salts.

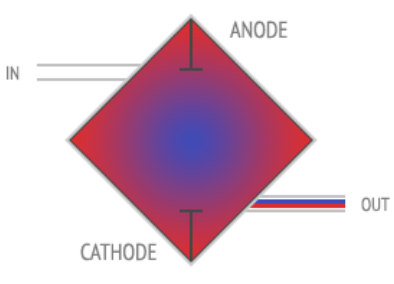

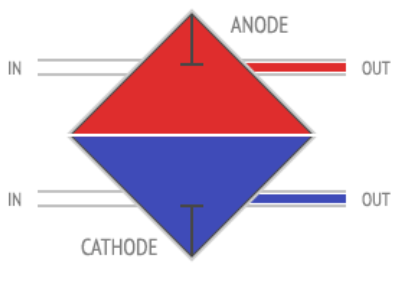

Our patented electrolytic cells, developed exclusively for Envirolyte generators, enable unipolar electrochemical water treatment. This means that we can isolate the negative and positive poles in the electrochemical water treatment process without interrupting the direct current. This simple approach makes our generators revolutionary. Thanks to Envirolyte technology, we can selectively electrochemically activate water, allowing the synthesis of up to two compounds for cleaning and disinfection simultaneously:

By anodically activating the water, our generators produce the Anolyte, a disinfectant solution whose main agent is Hypochlorous Acid (HCLO). This non-toxic substance enables environmentally friendly, socially responsible and financially sustainable processes, maintaining high-performance bactericidal power.

Through the cathodic activation of water, our generators synthesize Catholyte, a solution with the main agent Sodium Hydroxide (NaOH), which offers a powerful cleaning action with high degreasing power.

How our electrochemical activation technology works

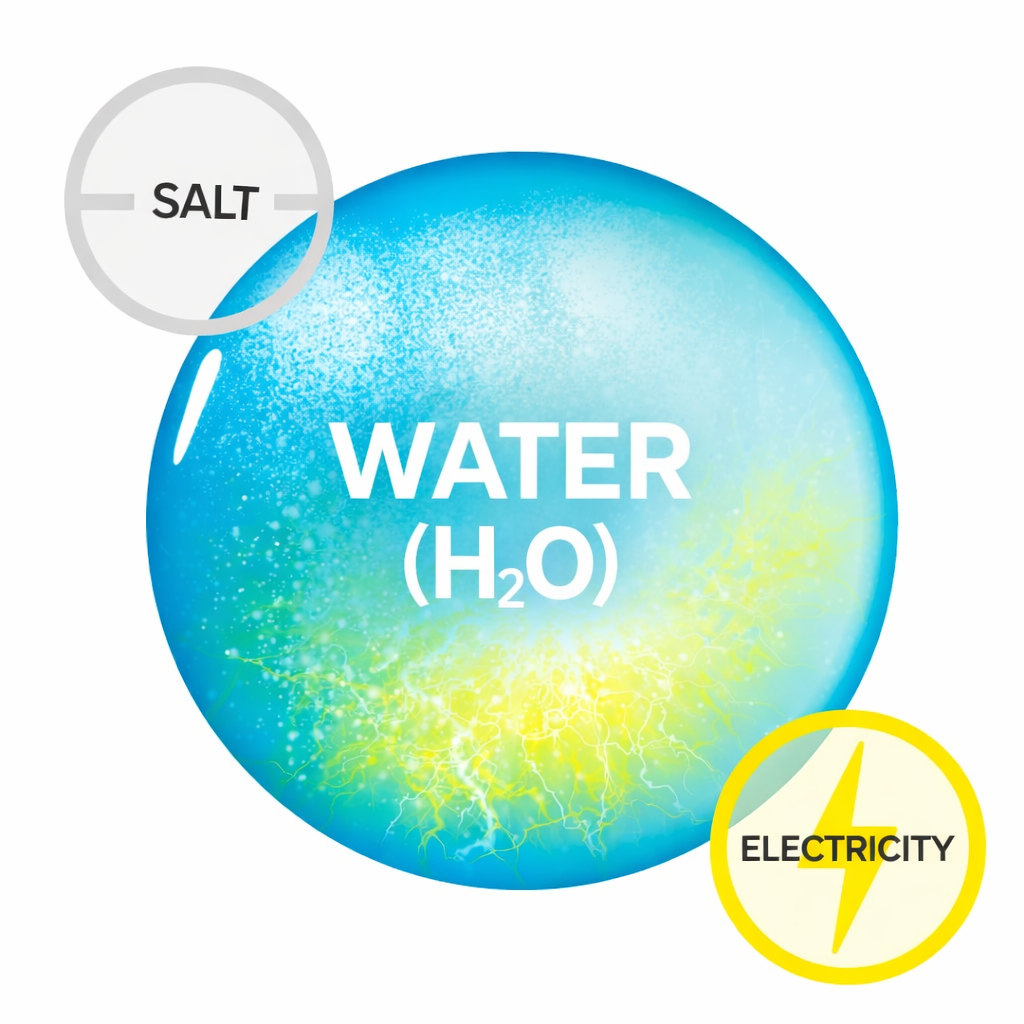

- System inputs: salt, water and electricity.

- System outputs: sodium hydroxide cleaner and hypochlorous acid disinfectant.

- Compact and easy to install system.

What do Envirolyte machines synthesize?

- Active ingredient: Hypochlorous acid (HCLO).

- Presentation form: clear, odorless liquid.

- Application: disinfection of surfaces, environments and in CIP (Clean-in-Place) processes.

- Differentiators: high electrochemical potential (ORP – 700~1200) and pH versatility (5.5 ~ 7.5) in its production.

- Benefits: Reduced costs, high bactericidal power, non-toxic to the environment and non-aggressive to humans.

- Active ingredient: sodium hydroxide (NaOH)

- Presentation form: clear, odorless liquid.

- Application: washing, degreasing action, flocculation, coagulation in CIP (Clean-in-Place) processes.

- Differentiators: high degreasing power without generating foam, versatility of pH (11 ~ 13) in its production.

- Benefits: Reduced costs, greater electrochemical potential (ORP – -800~ – 900) and reduced manual dilution.

Advanced technology for an exclusive process

Benefits

Effectiveness

Non-toxic products

Economy

Ecologically correct

Risk mitigation

On-site generation: practicality and savings

Check out the advantages of having an Envirolyte generator in your company

We use the term “on-site generation” to define the process of synthesizing cleaning and disinfection products at our customers’ own facilities. Something that was previously impossible has been made possible by Envirolyte technology. Our generators eliminate dependence on conventional chemical distributors and enable on-demand production to meet the needs of a wide range of industries.

Rather than relying directly on conventional chemical manufacturers and distributors, Envirolyte’s on-site generation systems allow customers to produce only the quantity needed to meet their sanitation needs. This not only reduces the risks associated with supply chain disruptions and logistical constraints, but also results in more effective and less aggressive chemicals. Therefore, Envirolyte solutions also help reduce the risk of environmental and labor liabilities.

With their wide versatility of applications, Envirolyte solutions are excellent for all sectors of the economy, and can be used for different functions within the same facilities. Envirolyte generators offer solutions for CIP (Clean-in-place) systems, misting systems, surface cleaning, manual spray systems, spray guns, spray bottles and more.

Envirolyte technology delivers solutions that use only water, salt and electricity, replacing the need for various chemicals. These solutions range from the simplest cleaning and disinfection to more complex sanitization processes for equipment, tanks, containers, work and rest areas, bathrooms, floors, among others.

Traditional cleaning and disinfection products

Envirolyte USA: Responsible Cleaning and Disinfection

How it's unique: A UNIQUE DESIGN

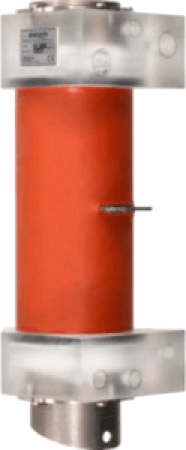

- Our patented diaphragmatic cells utilize innovative technology to deliver electrochemically activated solutions (Anolyte and Catholyte) effectively.

- Unlike conventional electrolytic cells, our diaphragm separates the Anolyte and Catholyte solutions, preventing their intermixing and the formation of a simple sodium hypochlorite solution.

- The Envirolyte USA cells boast variable Anolyte output capacities ranging from 20L to 1200L per hour, extendable up to 6000LPH with cell combinations.

- Constructed with titanium and rare metals, the round-shaped Envirolyte USA diaphragmatic cell ensures durability. The polymer or ceramic diaphragm between electrodes minimizes element breakage, even under severe conditions.

Statistics/Benefits:

- Safety: Hypochlorous Acid (HOCl) is naturally produced by white blood cells, making it safe, non-irritant, and non-allergic to humans and animals when used at correct pH and concentrations. Its application does not necessitate special personal protective equipment or training, ensuring worker safety.

- Effectiveness: On-site generation of ECA oxidants ensures solutions with constant potency. Unlike hazardous chlorine gas and traditional chemicals, ECA solutions degrade less over time, maintain purity, and exhibit superior disinfection power.

- Limitless Applications: ECA technology, utilized since the 1970s, finds application across various industries, from food processing to healthcare. The compatibility of ECA products with multiple surfaces eliminates the need for diverse surface-specific chemicals.

- Savings: Replacing conventional chemicals with ECA solutions can lead to up to 90% reduction in chemical costs. Moreover, the broad adoption of ECA products significantly reduces toxic effluent.

- Green: ECA is a natural and efficient cleaning agent, composed of salt, water, and electricity. It minimizes the consumption of harmful chemical reagents, contributing to environmental sustainability.

Markets:

- Home Health

- Skin Care

- Animal Health

- Dental

- Commercial/Bulk

- Pool & Spa

- Medical/Healthcare

- Optometry

- Schools

- Professional Offices

- General Business Spaces

- Senior Living

- Agriculture

- Bakeries

- Bottling & Beverage

- Hospitality

- Large Venues and Stadiums

- Food Processing

- Hatcheries

- Restaurants

- Brewers & Distillers

- Wastewater Treatment

- Transportation

- Cooling Systems

- Industrial Water Systems

- Sports Arenas

- House Cleaning

- Cruise Lines

- Water and Wastewater Treatment Plants

- Supermarkets

- Water Parks

- Egg Hatcheries