Seawater Anolyte Generators

New opportunities and applications

The use of seawater as a feed brine for Envirolyte’s activated solution generators (disinfection and washing) has always been a challenge and temptation for our scientists and engineers. The reasons for this are obvious: to eliminate the need for any mains water source and to make Envirolyte technology even simpler and more cost-effective. In addition, this technology broadens horizons for use in previously unreachable areas, such as off-shore/on-board and/or aquaculture applications, where there is a need for disinfection, sterilization and water purification.

The idea of seawater being used as the main and only feed for Envrolyte units is based on the chemical specifications of seawater, which is predominantly a solution of sodium chloride accompanied by some other salts. The concentration of sodium chloride is sufficient to generate the volume of active chlorine necessary to confer disinfectant properties to the final product – Anolyte generated exclusively with seawater.

Seawater Anolith Generators are designed to generate neutral anolyte and catolite in ANK, if required, out of seawater with salinity ranging from 5-7 PSU (brackish water) to 33-35 PSU (seawater), with active chlorine concentration in the range of 500 pm-1000 ppm.

Anolyte Generator ELA-850SW

Main features

- Full automation and easy operating procedures ensure fast delivery of safe, fast-acting disinfectant – ANK – neutral anolyte.

- The strength of ANK neutral anolyte in active chlorine concentration is preset during manufacturing and can be adjusted according to customer requirements.

- The generator control system is simple and easy to operate. It can be changed to suit different applications and conditions.

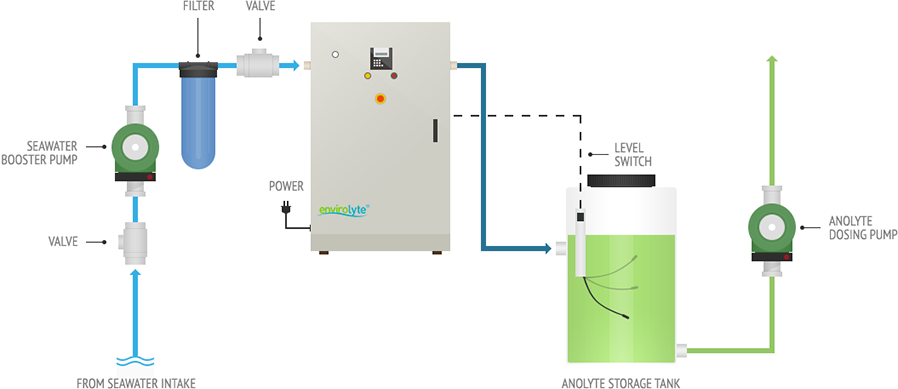

- Flow and pressure controllers are installed on the hydraulics to stop the Envirolyte unit if there is an interruption in the water supply and activate it as soon as the water flow resumes.

- The variable brine pump ensures the necessary dosing for any situation.

- The enclosures are made of non-corrosive materials and can be supplied according to customers' demand.

- The pipes and connectors are made of EPDM/PVDF plastic and are highly resistant to aggressive solutions.

- All input and output connectors are located on the sides of the housings to allow for simplified wall mounting.

- A simple on/off switch with power indicator allows you to manually start and stop the units.

- Level switches or ORP meter allow you to start and stop the units automatically.

- The Reset button allows you to start the unit regardless of the position of the level switches.

- The alarm is built into the unit, but can be installed in any remote area via external connection.

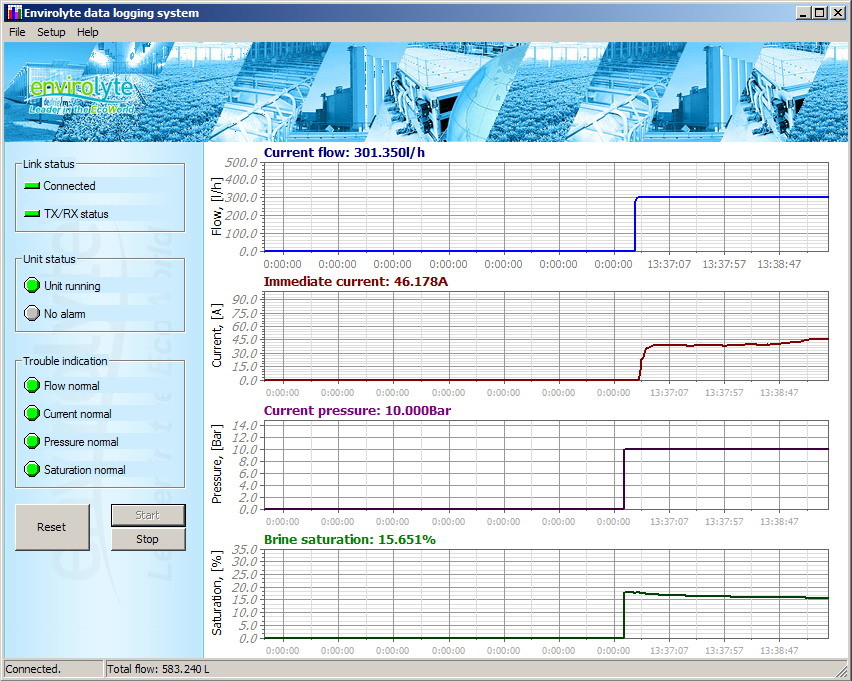

- PC/Internet control is optional for all Envirolyte Seawater Anolith Generators, which allows you to monitor the operation of the unit, diagnose and troubleshoot any potential problems from a control room at any location and distance from the installation site.

General Specifications

- The generators are manufactured with production capacity ranging from 40 LPH up to 6000 LPH of ANK neutral anolyte.

- The generators are mounted in polycarbonate, stainless steel or steel housings with motorized technology, reinforced polyester or chrome-plated aluminum.

- Power supply 380/230/110 VAС ±10%.

- Power consumption depends on the model and can range from 740 W/H to 10.5 KWT/H.

- Feedwater – seawater with salinity ranging from 5-7 PSU up to 33-35 PSU.

Economy

How much can I save with Envirolyte USA solutions?

Calculate and find out how cost-effectiveness makes all the difference

Responsibility

How toxic are my current processes?

Evaluate your current cleaning and disinfection processes compared to the solutions offered by Envirolyte USA.

Challenge

Take the Challenge of the Gallon

Sign up to participate in the challenge and receive free samples for testing.